Exploring Sculpt Nouveau Patinas and Metal Finishes: A Hands-On Workshop at AIDI

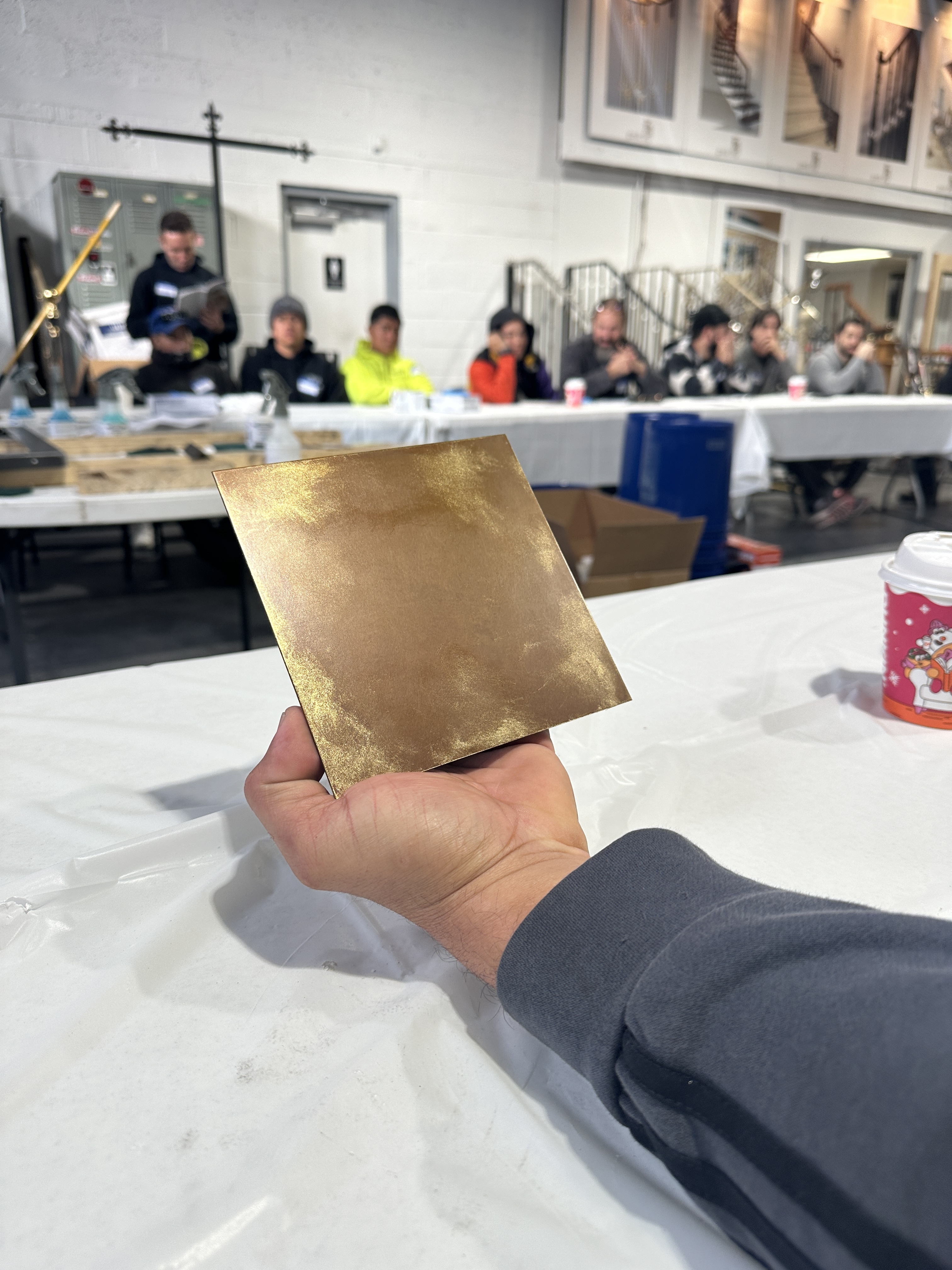

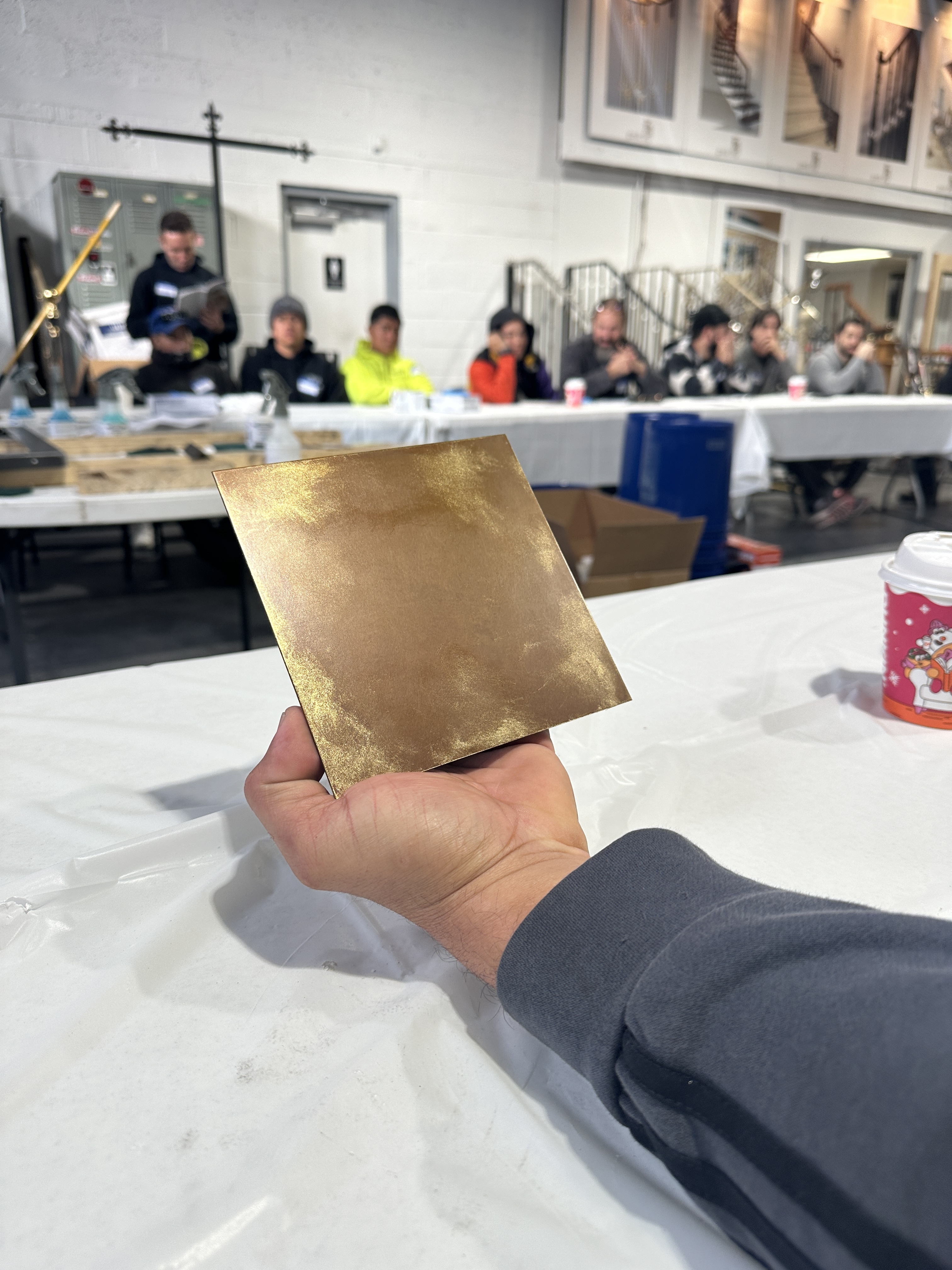

The primary focus of the workshop was the use of chemical patinas and metal finishes across several commonly used materials, including steel, stainless steel, copper, and brass. Attendees were able to see how the same patina reacts differently depending on the base metal, surface preparation, application method, and dwell time. In some cases, Tracey demonstrated how heating the surface can significantly affect color development and character — an essential consideration for fabricators producing decorative panels or architectural metal features that demand visual depth.

At Architectural Iron Designs, we work every day with professionals who understand that finish matters just as much as fabrication. A piece can be beautifully built, structurally sound, and perfectly installed — but the wrong finish, or a poorly executed one, can undermine the entire result.

That’s why AIDI recently hosted a hands-on workshop featuring products from Sculpt Nouveau, a leading brand of patinas and metal finishes. The goal of the workshop was to give metal fabricators and artisans the opportunity to explore techniques, materials, and real-world applications together.

The session took place at AIDI headquarters and brought together more than 25 attendees from as far away as Central Pennsylvania, representing a wide range of disciplines within architectural, decorative, and custom metalwork. Some were seasoned fabricators with years of finishing experience. Others were newer to patinas and looking to build confidence and understanding. Both groups benefitted from seeing the process in action — and from being able to ask an expert practical, job-site-driven questions.

The workshop was led by Tracey Stakelin, MFA, principal and founder of Delform Metal Fabrication in Rutherford, New Jersey. With more than twenty-five years of experience working across metal, concrete, and stone, Tracey brought both technical expertise and an artisan’s perspective to the session. Her approach emphasized experimentation, observation, and intention — key elements in achieving consistent, repeatable results with patinas.

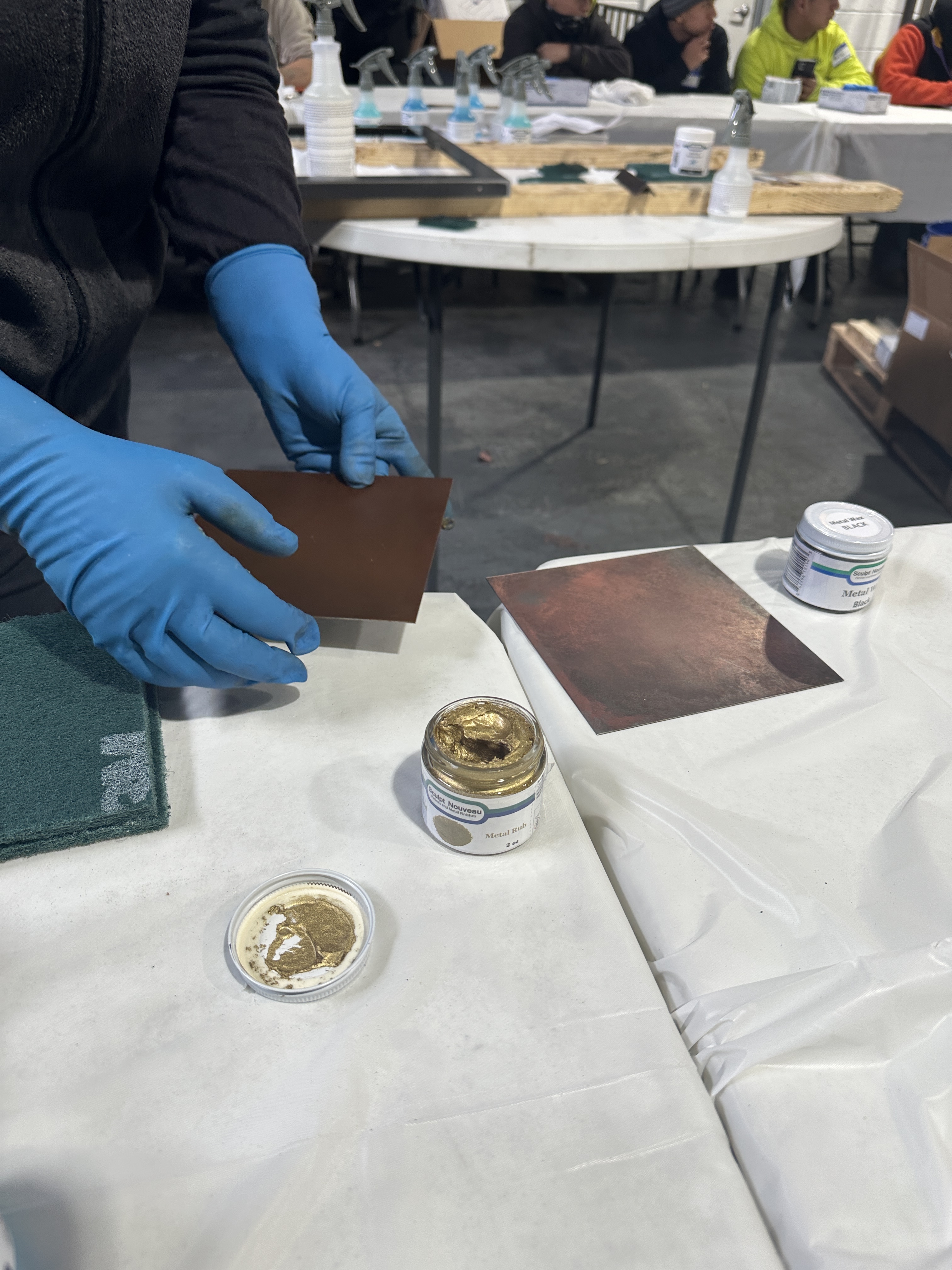

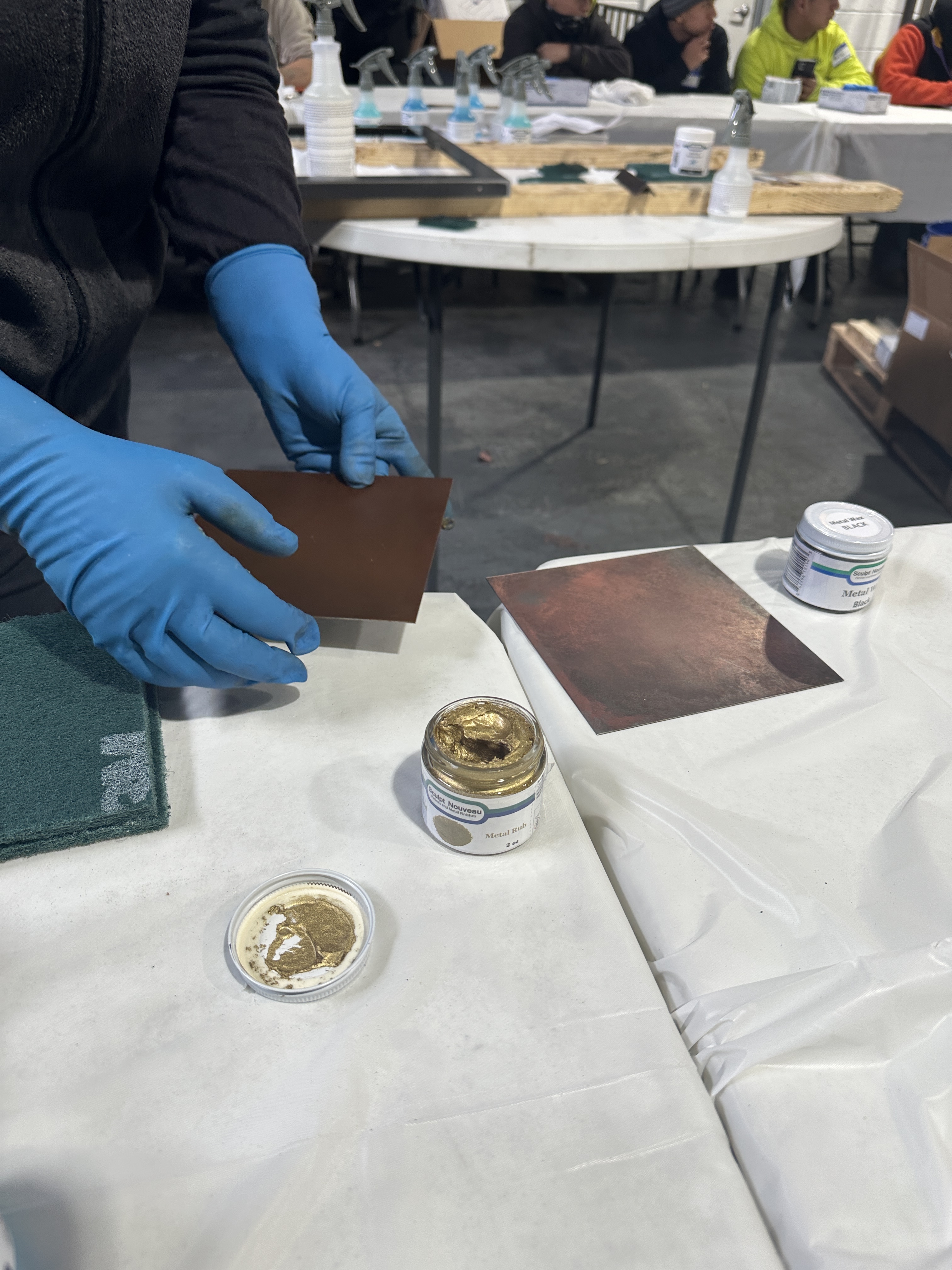

Throughout the session, surface preparation was emphasized as a critical step that should never be treated as an afterthought. Proper cleaning ensures the intended chemical reaction occurs and that finishes adhere as expected. Attendees watched as Stakelin and an assistant cleaned and degreased sample pieces, often using Sculpt Nouveau’s Metal Cleaner and Degreaser worked in with an abrasive pad to remove residue, mill scale, or oils left from fabrication. In some cases, acetone or denatured alcohol was used to remove moisture after patina application, helping to control the final result.

One of the most valuable takeaways for many participants was seeing how a single patina can produce a range of finishes. Rag application versus spraying, fast reactions versus slower builds, and selective treatments versus full coverage all resulted in distinct outcomes. For metal fabricators producing custom decorative work — or metal artists creating one-off architectural elements — this flexibility opens up creative possibilities without requiring entirely different products.

Sealing and protection were also discussed in detail. Once a desired patina effect is achieved, the finish must be sealed appropriately for its intended use. Tracey walked through the decision-making process around wax versus lacquer; explaining how environment, wear, and desired look should guide the choice. For example, architectural metals designed for frequent contact — such as doors, railings, and other touchpoints — often require a more durable lacquer, while static decorative metals may benefit from wax coatings that allow for easier maintenance and touch-ups in the future. The use of tinted or colored waxes to add nuance and depth over patinated surfaces was also demonstrated.

The workshop was intentionally interactive. Attendees were invited to test patinas themselves on provided samples, with Tracey offering guidance and troubleshooting in real time. Several participants even brought their own project pieces to workshop on site, including a newly fabricated hot-rolled steel frame and a century-old lantern from the Hershey Theatre. These real-world pieces sparked valuable discussion around restoration, finish matching, and balancing authenticity with durability.

At the conclusion of the session, AIDI President Jay Shah reflected on the value of demystifying the finishing process. Removing the fear around patinas—while also highlighting that there is rarely a single “correct” way to achieve a result—was a consistent theme throughout the day. He also expressed gratitude to Deborah Young, the owner of Sculpt Nouveau, for her partnership.

Workshops like this reflect AIDI’s ongoing commitment to supporting the professionals we serve. Beyond supplying architectural metals, decorative panels, and specialized components, our goal is to provide insight, access, and shared knowledge that help skilled tradespeople do their best work.

If you’re interested in attending a future demonstration or training session focused on metal finishes, patinas, or related techniques, we encourage you to reach out to us at aisales@archirondesign.com. We’re always glad to help you explore what’s possible—and to support the work you’re building next.